ROS-controlled Joints

Series of robot joints using state-of-the-art technology to design customized collaborative robotic systems based on application

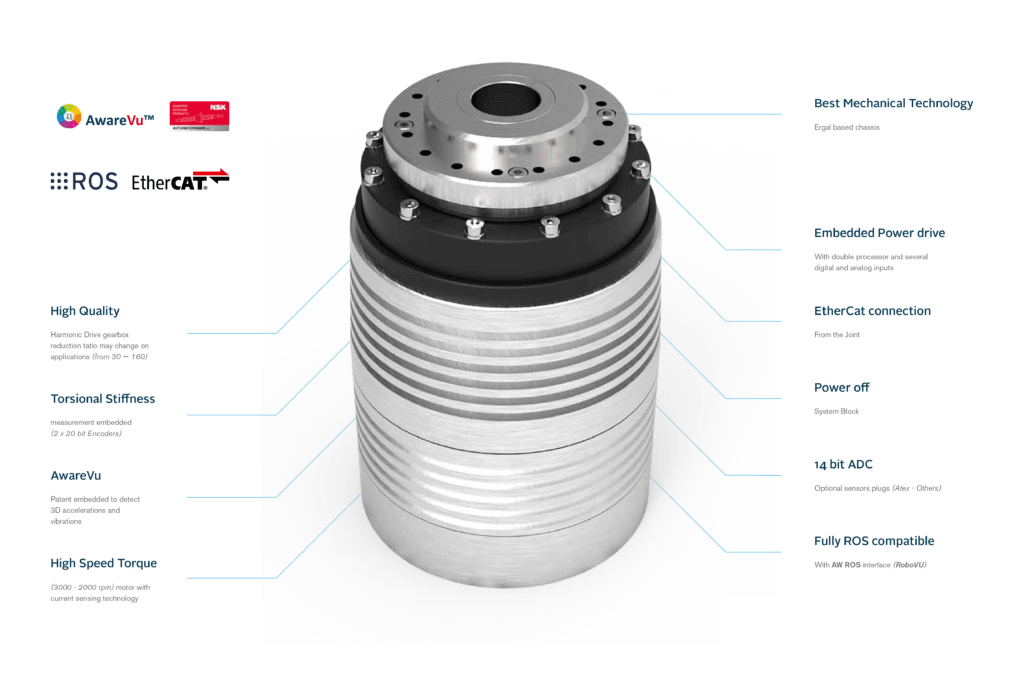

Available in 5-sizes (14-17-20-25-32) joints can be used in a wide range of applications as single units to deal with accurate rotational engagements with high torque and minimum size thanks to a harmonic drive reducer, which can be defined with various reduction ratios

J-14, one of the smallest joints in the world, allows high speed rotation while maintaining 28 Nm maximum torque

J-32, based on a high performance torque motor, develops a maximum torque of 353 Nm and a nominal 220 Nm thanks to a high performance HD gearbox.

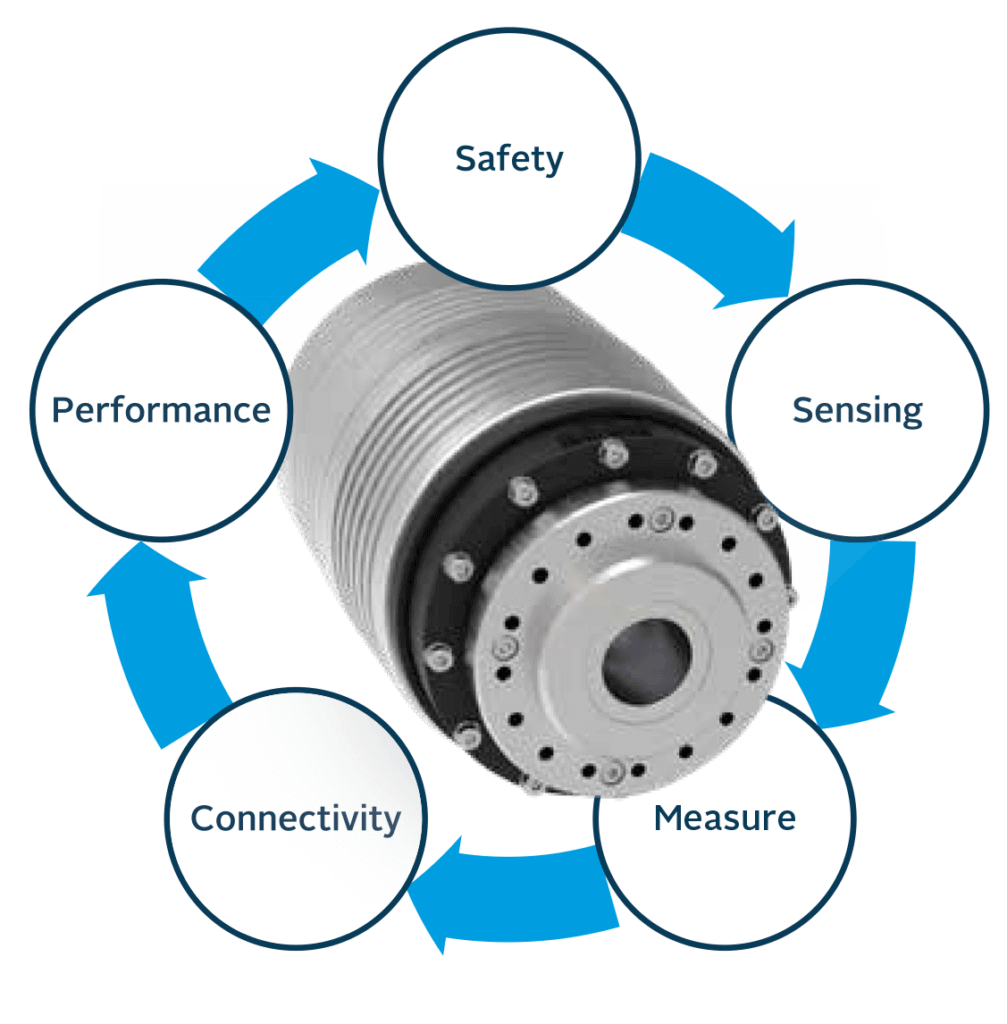

3 safety systems prevent possible collisions with human or objects: torque measurement through the control of the high resolution current, electronic measurement of the torsional rigidity of the reducer, contact detection device for a instantaneous/immediate response with sensitivity up to fractions of Nm.

Two 20bit magnetic technology encoders allow high positioning accuracy with a resolution of 1,000,000 levels of quantization on 360 ° of rotation

Each joint contains a very sophisticated electronic controller to communicate through EtherCAT bus with robot controller based on Robot Operating System (ROS), safety features during collaborative operations are assured with integrated sensors and accelerometers.

Solutions for the factory of the future

Copyright 2024 © All rights Reserved