The best combination of speed, strength, accuracy and productivity.

The belts used are made of polyurethane with steel strands and the tooth is coated to reduce noise at high speeds.

The belt slides inside guides slots created on the profile that protect the internal mechanics from dust or processing residues.

A steel sheet, passing inside the trolley, allows additional protection to the unit. (High Protection versions).

Belt maintenance operations can be carried out easily.

Belt replacement and tensioning can be carried out without disassembling the unit from the application.

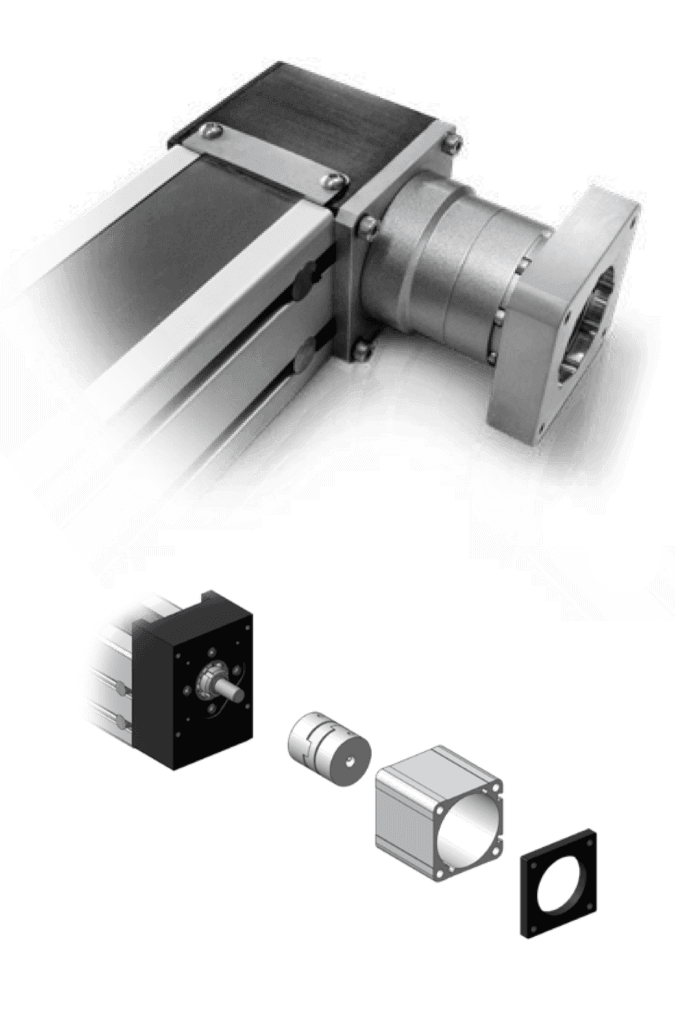

The motion can be transmitted directly by fixing the motor shaft with shrink discs or conical bushes or with protruding shafts and coupling joints.

Planetary gearboxes are available, having high efficiency and precision, to optimize motor performance based on the load to be moved.

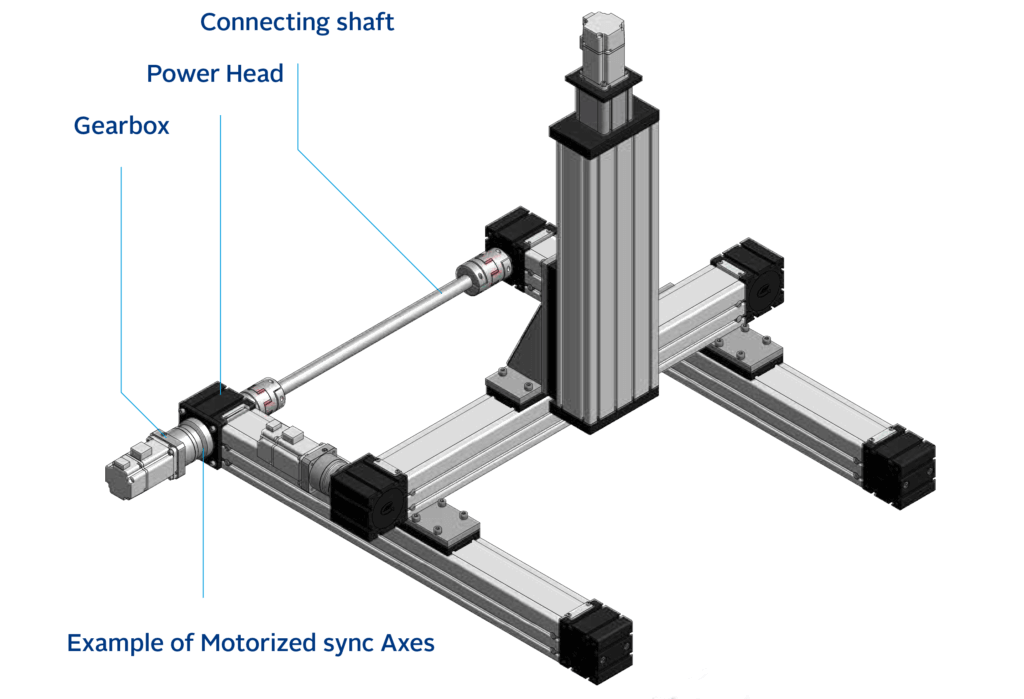

A wide availability of accessories allows the creation of single or multi-axis solutions.

Wide choice of high performance gearboxes, Servo Stepper or Brushless motors, variety of return shafts and appropriate interface plates.

Furthermore, there is good accessibility for periodic lubrication.

The return head is equipped with a tensioning system.

Any adjustment is possible without removing the load from the trolley.

The drive head is equipped with zero-play pulley with hole for shrink disk or conical bush.

The direct fixing to the driving pulley of gearboxes and motors, through suitable flanges, ensures good rigidity and allows high dynamics.

It is possible to supply units complete with planetary gearbox and motors.

In the version with screw, the nut is fixed inside the trolley.

The protection of the screw is ensured by the steel sheet that runs inside the trolley.

The drive head is equipped with fixing holes for connecting adapter or belt transmission.

It is possible to supply units complete with motor adapter, joint and interface flange for the required motion system.

The Axis Motion Line series includes a series of accessories suitable to support any application:

• Compact planetary gearboxes with extremely low backlash and high efficiency

• Flanges and shrink discs or conical bushes for perfect compatibility with Motors or Reducers

• Return shafts in accordance with the engines used

• Various types of Motors and Drivers to complete the application

• Sensors for mobile carriage and / or fixed carriage units and mobile profile

• Additional trolleys for adequate load distribution

• Sensors of various types such as Hall effect, induction or electromechanical with profile or bracket fixing

• Brackets and connection systems for XYZ configurations or adapters for connection to the SM Series

Copyright 2024 © All rights Reserved