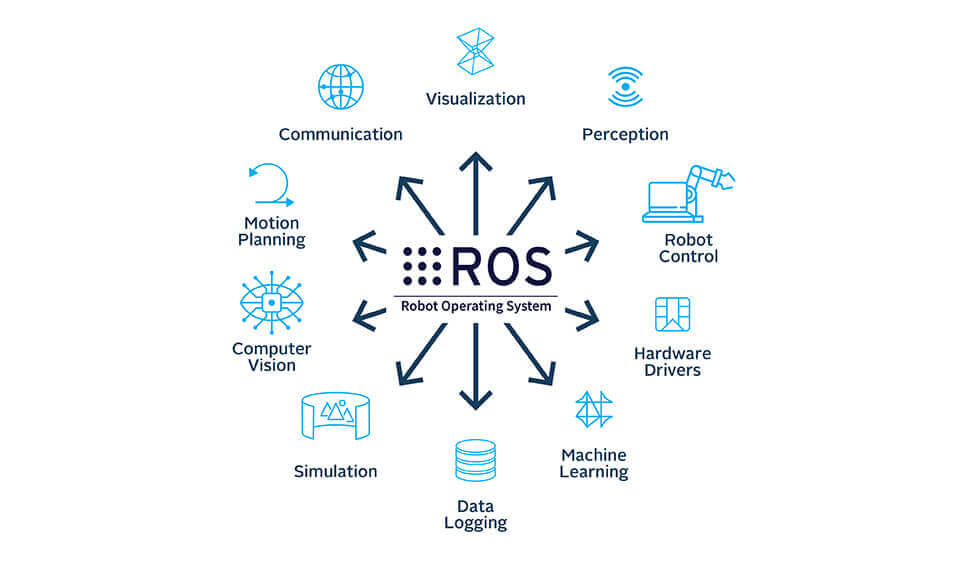

ROS (Robot Operating System) is an open source development environment composed of a set of software libraries, tools and algorithms for the development and programming of robotic and advanced automation systems. It is a constantly evolving modular system, which grows thanks to the contribution of its developer community.

ROS allows you to program complex kinematics for a wide variety of applications and to synchronize robots on industrial buses such as EtherCAT or Profinet, making them synchronous with all other devices on the network. Specific packages continuously updated such as SROS protect the system from cyber attacks.

ROS is a fundamental component of all AutomationWare robotic solutions and drives. All our collaborative robots are supplied with the installation of a basic ROS package that includes all the drivers and a 3D model of the cobot, but also tools for locating and using maps and simulators for planning movements.

Do you want to start planning the tailor-made solution for your application or design and test individual software modules offline? We provide simulation software with 3D robot models, test environments and a pre-configured and easily adaptable navigation package. You can simulate all the sensor data, create maps and make the cobot move in the virtual environment. An opportunity to see the driving behavior of our collaborative robots, try how they react to different conditions and obstacles and test your changes.

The first step to get to know Robot Operating System is to connect to the ros.org site where you can consult the list of compatible platforms, and have a series of information, starting with the first installation and the instructions for taking the first steps

A robotics expert, from AutomatioWare, will contact you to answer all your questions and support you in any new project.

Copyright 2024 © All rights Reserved